Company Profile

Greeting

From “Nara,

which has no oceans”

to

“the oceans of the world”

MIZUNO STRAINER INDUSTRIES CO., LTD.

Representative Director:Nobuaki Mizuno

Since its establishment over 60 years ago, Mizuno Strainer Industries Co., Ltd. has continually faced challenges found in the world’s oceans as a specialist strainer manufacturer. We have been able to stably maintain our business thanks to the unwavering support of our business partners and suppliers from the founding of our company until now, and the efforts and enthusiasm of our employees who work hard to create good products. I would like to take this opportunity to offer my sincerest thanks to all of you.

We have continued to create strainers which remove impurities from water and oil, and continued to build our experience and achievements related to the filtering of water and oil. However, there are still unexplored areas where phenomena we have not yet experienced occur, such as the environmental problems arising all over the world, where the importance of strainers continues to grow. We will continue to strive to be a company that can be relied upon to stand side-by-side with our customers, to contribute to the solution of these issues, and to be relied upon so that customers can believe "Mizuno will know the answer" and "Mizuno can handle it".

The manufacturing environment has also changed significantly over these past 60 years, and I believe that we will always need to continue developing and growing in order to maintain our unchanging quality and advance our techniques and technologies. We will continue to value our core beliefs, maintained since the founding of the company, of "be humble" and "it is the heart that is important", and we will continue to change, create, and face challenges, moving ever forward so that we can take on "large jobs all over the world" while being a "a small company from Nara".

Company Profile

| Company name | MIZUNO STRAINER INDUSTRIES CO., LTD. |

|---|---|

| Location | 5-41, Zaimoku-cho, Yamato-Takada-city, Nara-pref. 635-0011, Japan Phone +81-745-52-0581 Fax +81-745-22-6005 |

| Incorporated date | 1st March, 1959. |

| Paid up capital | Japanese Yen 10,000,000- |

| Representative Director | Nobuaki Mizuno |

| Main function & product lines | Manufacturing, planning and selling of various strainers and filters for use of ships and factories sited on land. ●Cast iron strainer ●Steel plate strainer ●Other strainers and filters specially designed |

| No. of employees | 35 |

| Annual turnover | Japanese Yen 1,000,000,000- |

| Banks | Resona Bank Limited, Kashihara Branch. The Nanto Bank, Ltd., TakadaHonmachi Branch. The Shoko Chukin Bank,Ltd. Nara Branch. |

Our history

| March 1959 | Hiroyoshi Mizuno who was born in Gifu Prefecture founded Mizuno Valve Industries in Kitakyobate-cho, Nara City as a manufacturer of cast iron valves for ships. |

|---|---|

| June 1961 | Reorganized as Mizuno Valve Industries Co. Ltd |

| February 1964 | Head office and factory moved to newly built facilities in Yamatotakada City. |

| May 1968 | Name changed to Mizuno Strainer Industries Co. Ltd and made a new start as a specialized manufacturer of marine strainers. |

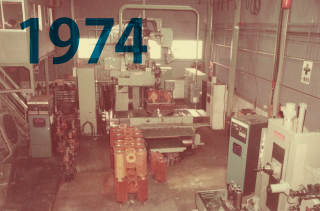

| February 1974 | Purchased 1,550 m² of land from the city and expanded the factory. |

| April 1974 | Introduced an NC machining center (50CN) and NC lathe which was a first in the marine valve industry. |

| November 1977 | Paid-up capital increased to 10 million yen. |

| November 1981 | Founding President Hiroyoshi Mizuno passed away and Yoshiko Mizuno was appointed as President and CEO. |

| July 1982 | Accredited as a factory authorized to use Japanese Industrial Standards (JIS) labeling. |

| September 1991 | Introduced a CAD system (MICRO CADAM) for design. |

| March 1994 | Updated the 500 mm horizontal machining center (10 pallets). |

| April 1997 | Introduced a 1,600 mm bore face center. |

| October 1999 | Started to procure castings from China. |

| March 2002 | Introduced an IGV 1,000 mm CNC vertical grinding machine. |

| December 2002 | ISO9001:2000 certification |

| April 2006 | President Yoshiko Mizuno was awarded the Medal with Yellow Ribbon. |

| May 2006 | Acquired JIS product certification. |

| November 2006 | Built the Magarikawa Branch Plant in Kashihara City, Nara Prefecture and Introduced a 800 mm horizontal machining center to expand production capacity. |

| March 2008 | Introduced a 3D CAD/CAE CATIA system. |

| June 2008 | Selected by the Ministry of Economy, Trade and Industry as one of the "300 Dynamic Monozukuri (Manufacturing) SMEs". |

| August 2008 | Started to procure castings from Thailand. |

| October 2010 | Introduced a new design of can water strainer with a maximum diameter of 650A made of cast iron to accommodate larger ships. |

| April 2010 | Introduced a 5-axis vertical machining center with a Φ630 mm × 520 mm turning center. |

| April 2013 | Yoshiko Mizuno is appointed Chairman and Nobuaki Mizuno is appointed President and CEO. |

| April 2014 | Exhibited at the SEA JAPAN 2014 (Tokyo) maritime exhibition (first time to exhibit in Japan). |

| May 2014 | Introduced a new production control system. |

| May 2015 | Exhibited at BARISHIP 2015. |

| July 2015 | Introduced a KBT11 table-type CNC horizontal medium milling machine. |

| October 2016 | Renewed ISO9001:2015/JISQ9001:2015 certification. |

| June 2019 | Introduced 3D CAD SOLIDWORKS. |

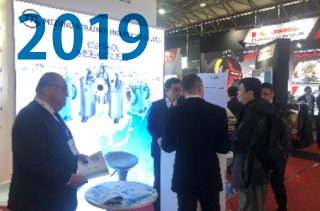

| December 2019 | Exhibited at the MARINTECH CHINA 2019 (Shanghai) maritime exhibition (first time to exhibit overseas). |

| March 2020 | Introduced a CVG-9 900 mm CNC vertical grinding machine. |

Main equipment

| 1450mm Horizontal machining-center (HMC+110) | 1 Unit |

|---|---|

| 800mm machining-center(NH8000) | 1 Unit |

| 1400mmx1750mm Horizontal Boring & Milling Machine(KBT-11Z) | 1 Unit |

| 630mm machining-center (HG630) | 1 Unit |

| 500mm machining-center (HN50D,HN50E) | 2 Unit |

| 1600mm NC vertical lathe (VT4-16N) | 1 Unit |

| 1000mm NC turning-center (TDC2-10NS) | 1 Unit |

| 510mm Vertical MC (NEXUS 510C) | 1 Unit |

| 400mm machining-center (PN400) | 1 Unit |

| 1000mm Vertical CNC grinding machine (IGV-10N) | 1 Unit |

| 900mm CNC Vertical Multi-Process grinding machine (CVG-9) | 1 Unit |

| 350mm NC grinding machine (OGM350EXⅢ) | 1 Unit |

| 12” CNC Turning center (QTN300) | 1 Unit |

| 15” Mill-center lathe (INTE400) | 1 Unit |

| 10” CNC Turnig center (QTN250) | 1 Unit |

| 10” 1‐saddle CNC lathe (LB3000EX) | 1 Unit |

| 15” NC lathe (TG40) | 1 Unit |

| Table type boring machine | 2 Unit |

| Lathe | 4 Unit |

| Swing type hydraulic shear (SHS) | 1 Unit |

| 3 rolls bending machine | 1 Unit |

| Quick bender (BU-S) | 1 Unit |

| Spot welding mahine | 3 Unit |

| Semi-automtic welding machine | 2 Unit |

| TIG welding machine | 2 Unit |